IoT Solutions: Industrial / Logistics

Overview

Industrial Overview

FCL Components' IoT solution is based on Wirepas Mesh and comprises multiple components which form robust and reliable mesh networks for industrial IoT applications, including the tracking of assets and inventory levels in factories, laboratories and the like. The asset tracking solution features our wireless radio module for embedded network design, a mesh sensor unit, and a mesh tag unit—along with components from our IoT ecosystem partners. All components are battery operated and consume minimal power, enabling effortless mesh sensor network installation.

The 2.4GHz Wirepas mesh network is constituted from FCL Components anchors and features some major advantages:

1. Highly scaleable: no limitation on the number of the devices added to one network

2. Self Healing: when removing an anchor or sensor the network re-establishes the best possible route

3. No single point failure: any device can be a router at any time

Networks designed using Wirepas mesh 2.4GHz offer airtight security and are fully autonomous. Their ability to select the best radio communication channel and adjust radio communication power levels to specific environments increases their reliability, even on noisy factory floors. The network offers airtight security by ensuring unknown nodes can’t join a network without right network address/channel/keys. These networks become the backbone of asset tracking and environmental monitoring applications.

Click the individual tabs above for more detailed information about how FCL Components' IoT solution supports asset tracking applications, as well as smart lighting and sensor-based environmental monitoring applications for the industrial sector.

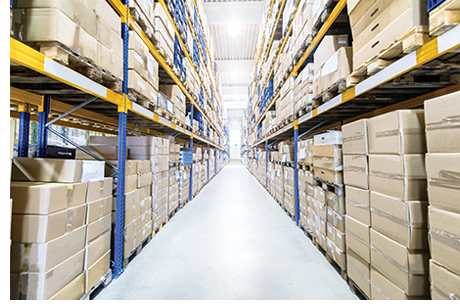

Logistics Overview

Comprising a wireless radio module, a slim mesh tag, and mesh sensor options, FCL Components' Wirepas Mesh units allows developers to build robust, reliable mesh networks for a variety of logistics applications, such as tracking pallet positions throughout the warehouse and locating goods in long-term storage. Through their sensor component, these networks can also be leveraged as a backbone for monitoring environmental conditions (e.g., temperature, humidity, and CO2 levels) to which goods are exposed while moving through facilities and at the moment of shipment.

Networks that incorporate Wirepas' mesh network technology offer the advantage of being fully autonomous, making them especially viable for deployment in large warehouse facilities. They are also highly reliable, with the capability to choose the optimal radio channel and adjust the radio communication power level to suit specific environments. Networks’ end node can be put into “sleep” mode to conserve battery power in cases where no pallet movement is detected.

Click the individual tabs above for more detailed information about how FCL Components' IoT solution supports asset tracking and environmental monitoring applications for the logistics segment.

Asset Tracking

Being able to trace and track your assets is hugely important when transporting and storing goods. This is easy to achieve through FCL Components' Wirepas Mesh units.

Logistics

Wirepas Mesh units enable the tracking and tracing of various devices during in-house transportation and stock renewal. The solutions provide greater insight into the location and routing history of forklifts, pallets, wire carts, stock carts, pallet carts, lifts, and stackers.

Tagging pallets, containers, or plastic storage boxes allows real-time insight into the storage location of particular goods.

Industrial/Production

Besides storing products in production facilities, FCL Components' Wirepas Mesh units can assist with raw material process control during production. Tagging storage containers and boxes helps to provide insight into which batch of raw materials or components have been delivered to the production line, at a preferred time accuracy interval.Even when these assets are on the road, truck cargo space can be recognized as a mobile warehouse to monitor the asset location, conditions like temperature, humidity, accelerations or shock level with mobile gateways throughout the journey.

By using 4G mobile gateways, the whereabouts of the containers in transit can be tracked through truck localization.

Given the added visibility and transparency provided by FCL Components' asset tracking, quality control can be greatly enhanced.

How does it work?

Place batteries, affix router devices (anchors) to walls and ceilings, and place tags on assets. That’s it for installation. The devices can also be USB powered.All devices are able to transfer data through the mesh network. The gateway forwards the data to the server.

- Highly scaleable

- Self Healing

- No single point failure

- Extremely low interference

- Low cost

- Long battery life

The positioning data and sensor data can be extracted from the Wirepas backend with API. Then the user can visualize the data on their platform.

Expansion

Our partner’s lighting equipment can work with FCL Components Wirepas Mesh units. Those lighting fixtures can be utilized as router devices becoming the backbone of the network.Environment Monitoring

Measuring is knowing, especially with regards to non-visual environmental conditions, such as air quality, humidity, and barometric pressure. Environment Monitoring in logistic and industrial environments can serve three major purposes:

1. Monitoring the working environment

Monitoring variables such as temperature, humidity, noise, and CO2 levels can help to optimize the work environment, keeping staff safe and healthy. The data output can be viewed on a dashboard (managed by an ecosystem partner) and used to trigger actions such as ventilation or heating/cooling.2. Machinery Monitoring

In certain production environments, monitoring the condition of production machinery, including its temperature and noise levels, can help with the identification of issues at an earlier stage, preventing potential problems such as overheating or corrosion. The dashboard can serve as a trigger for staff to check the machine, so maintenance can occur before component failure.3. Storage Conditions

The storage environment can be vital to the condition of the products in a warehouse or during transportation, whether this relates to fresh food, paper, or microchips. Every type of product or stored asset requires a certain level of humidity, temperature, or illumination to remain in peak condition.FCL Components' environment monitoring sensors are able to track a wide range of environmental metrics:

- CO2

- Temperature

- Humidity

- Barometric pressure

- Illumination

- 3-axis acceleration

- Sound levels

The 4G mobile Gateway also allows for data transmission during transportation, enabling real-time environment monitoring during transport, helping transported goods and food to arrive at their location in mint condition.

FCL Components' environmental monitoring sensors also assist in tracking environmental conditions of inhouse stored assets to ensure those assets deliver optimal performance - at all times.

Smart Lighting

Warehouses and production areas can benefit tremendously from Smart Lighting. Energy saving is a major but not a sole benefit, three major benefits:

1. Energy efficiency and sustainability

Smart lighting is highly controllable; lighting schemes can be set to match the surrounding environment. This limits the use of unnecessary lighting.Occupancy sensors help to prevent active lighting of unused areas.

Daylight compensation, measures the day light available and calculates the amount of additional lighting required to reach the most optimal lighting scheme.

2. Optimized lighting for the activity

The right lighting scene for the job, helps staff to do their job in the most optimal environment. By example a production environment would require a different lighting setting than a storage area.3. Flexibility

Now a-days many warehouses are set-up to be flexible, allowing for re-configuration when required. Lighting systems need to facilitate this and can support warehouse configuration by revising lighting schemes. By example, when changing the storage area to the work environment, the lighting scheme can easily be adjusted to accommodate its new functionality.FCL Components works with eco-system partners on lighting solutions, their advanced lighting systems include FCL Components mesh modules. FCL Components' mesh modules are available for manufacturers interested in to turning their devices IoT ready or integrating the device into the mesh network