Touch Panels: Flush Surface Touch Panels for Medical Devices

In April, FCL Components’ Flush Surface Touch Panel was a finalist in the 2024 Medtec Innovation Award program at Medtec Japan, the premier tradeshow for the design and manufacture of medical devices. This event is Japan's only exhibition and seminar dedicated to medical device design and manufacturing. |

FCL Components’ Flush Surface Touch Panels are ideal for medical equipment

- Better noise immunity

- Resistant to environment / blood, saline, or body tissues

- No complex tuning or setup required

![]()

- Sleek design

- Easy to clean

- Improved water resistance through use of integrated buttons

- Logo printed and colored frames available

![]()

- “Work when pressed” structure

- Any object can be used for input

![]()

- High transparency and light operability

![]()

Development Background

Touch Panel Issues in the Medical Field

| PCAP | RTP (Resistive Touch Panel) | |

|---|---|---|

| Detection Principle | Capacitive Sensor | Switch |

| Current Situation | Since input detection principle uses a sensor, malfunctions cannot be completely prevented. In recent years, with the spread of the capacitive touch technology, the number of malfunctions in the market has increased rapidly. | Resistive touch technology does not use sensors, so erroneous input is not an issue. RTP panels also meet market needs including light touch force operation, attractive styling, and full-flat design. |

| Issues |

|

|

Development of Touch Panels Suitable for Medical Applications

Most important touch panel characteristics for medical use cases:- First priority: Erroneous input does not cause malfunction. This is critical in the medical field

- Second priority: Appearance, operability, and cleanliness

FCL Components’ Flush Surface Touch Panels satisfy these key priorities using reliable resistive touch technology, which delivers the same ease-of-use as projected capacitive touch panels.

| Function | Features | RTP | PCAP | FCL Components' Flush Surface Touch Panel | Market Requirements |

|---|---|---|---|---|---|

| Accessibility | Universal input*1 | ◎ | △ | ◎ | ◎ |

| No malfunction (noise, water droplets) | ◎ | △ | ◎ | ◎ | |

| Reliable input | × | × | ◎ | ◎ | |

| Usability | Appearance | △ | ◎ | ◎ | ◎ |

| Cleanliness | △ | ◎ | ◎ | ◎ | |

| Light operation with multi input | △ | ◎ | 〇 | 〇 |

Notes: *1: Input based on universal design that anyone can operate fairly and accurately with pen/nail/glove/prosthetic hand/elderly, etc.

Symbols:

◎: Very Good | 〇: Good | △: Acceptable | x: Unacceptable

Medical Market Specifications:

◎: Specifications must be met | 〇: Optional requirement

Features of FCL Components' Flush Surface Touch Panels

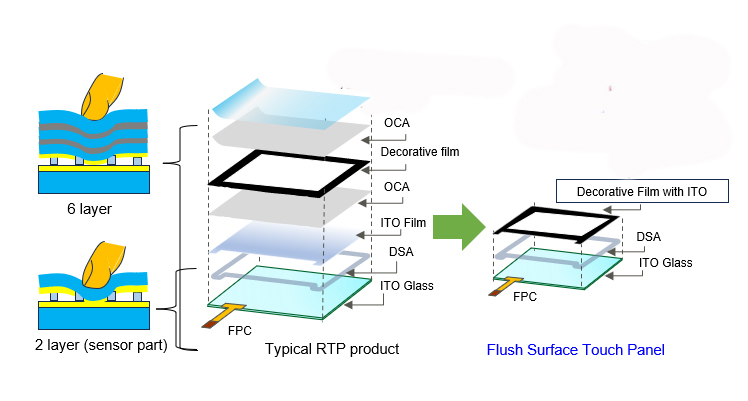

Structure

A typical resistive touch panel has a total of six layers, which makes it difficult to design a sleek and high-performing panel. Our flush surface touch panel has a two-layer structure, which greatly improves operability and appearance. Decorative printing is added to the topmost surface film.

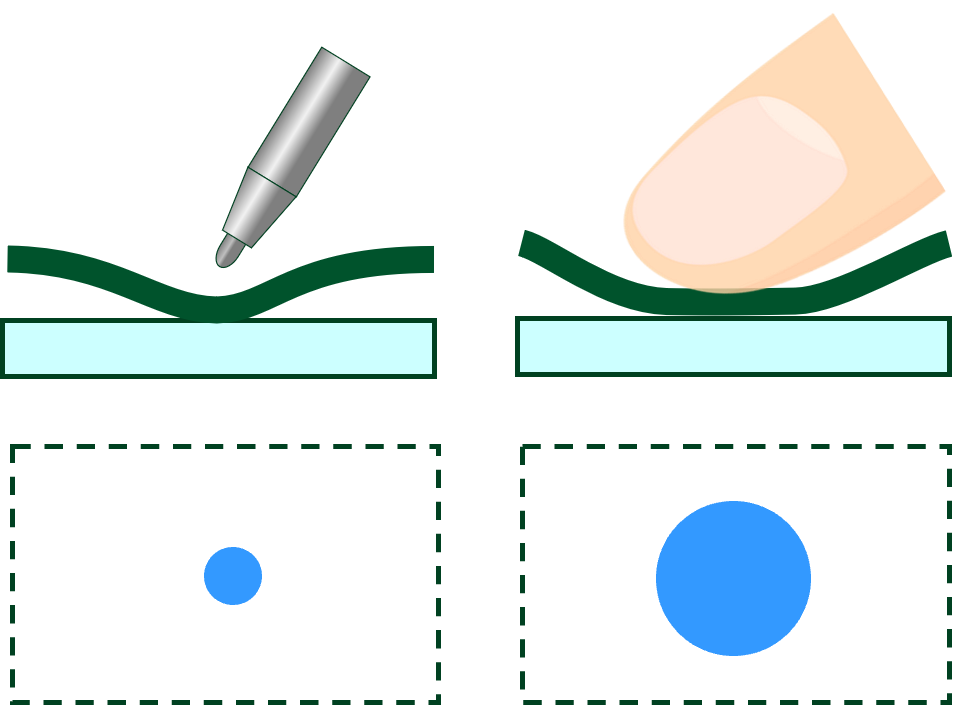

Pressure Level Detection - Diverse Touch

FCL Components has also developed firmware capable of detecting the size of the touch input area. This enables improved dual-touch (two-finger) operation. It can also detect the amount of pressure of a single touch.

- Dual Touch – Improved Gesture Accuracy

Our unique two-point detection method using a 4-wire touch panel makes it possible to improve the accuracy and stability of two-finger gestures.

- Pressure Level Detection (Single Touch)

Our software can detect of the amount of pressure used in the input area. This makes it possible to distinguish between pen and finger input, and to change application behavior according to the amount of finger pressure.

For more information:

Flush Surface Touch Panels LeafletContact Us